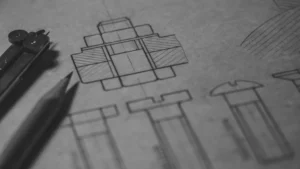

Design for Manufacture (DFM) is an essential aspect of CNC (Computer Numerical Control) production, as it ensures that parts and components are designed in a way that can be easily and efficiently manufactured using CNC machines. Here are some important considerations for DFM for CNC production:

- Material selection: Choosing the right materials for a part is critical in ensuring that it can be machined effectively. Materials that are difficult to machine or prone to warping, such as some plastics or certain metals, may need to be avoided or modified in the design.

- Part orientation: The orientation of the part during the machining process can significantly affect the quality and efficiency of production. Designers should consider the orientation of features and how they will be machined, including tool access, clearance, and support.

- Part geometry: Parts should be designed with simple and uniform geometries that can be easily machined. Complex geometries can increase machining time, which can result in higher production costs.